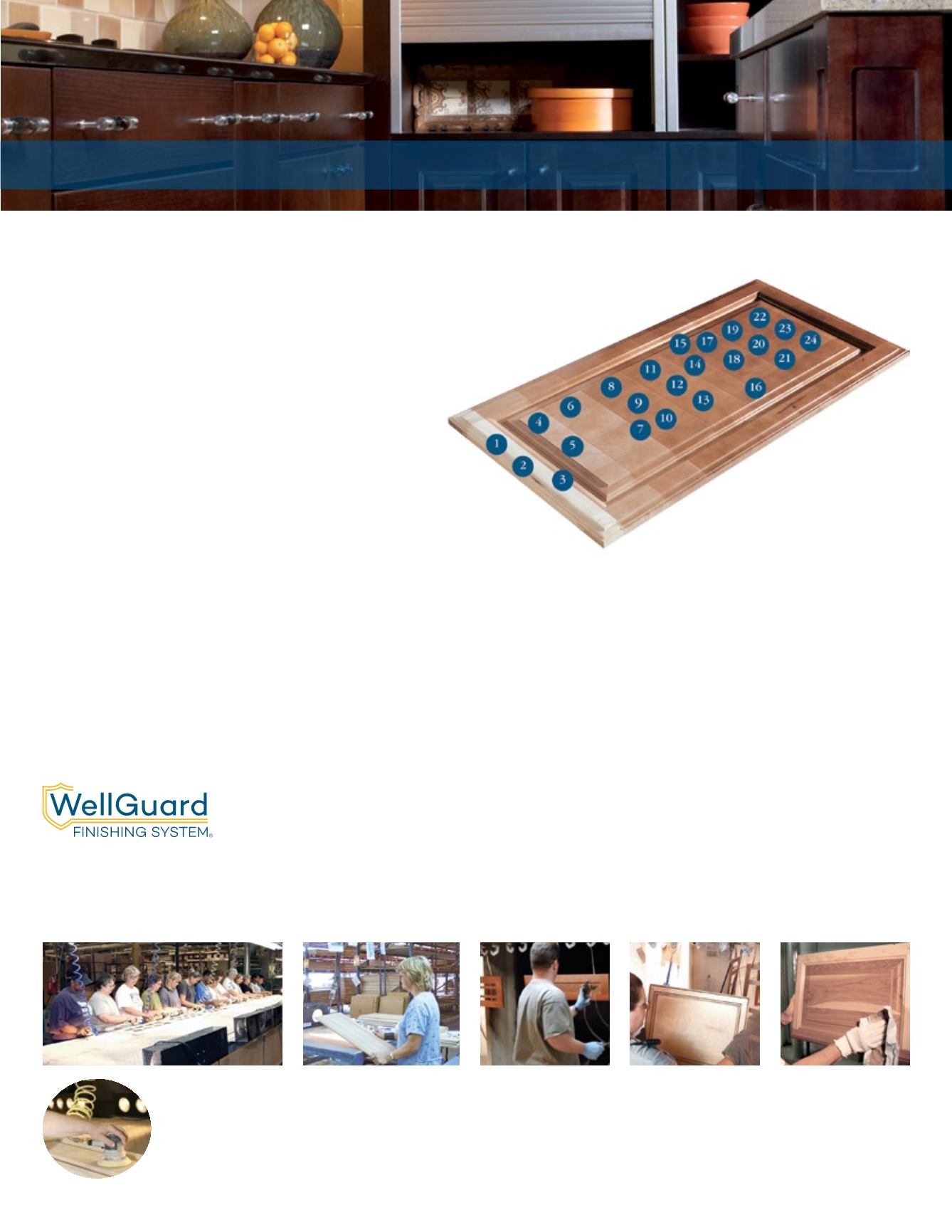

19

1.

Hand select

the finest wood

2.

Manual

hand sanding line

for a smooth consistent finish

and cross grain elimination

3.

Dust particles removed and

quality inspected

4.

A sap stain is applied to

tone and balance

the color and

grain

5.

Grain enhancing dye stain adds color depth

6.

Hand rubbed

wiping stain applied for complete color

coverage

7.

The surfaces are air dried and

inspected

for color

8.

The first coat of

durable catalyzed sealer

is applied

9.

Oven-cured

providing a tough, durable, baked-on finish

10.

Hand sanded

with fine grit sandpaper and quality inspected

11.

The second coat of catalyzed

melamine enriched

sealer is

applied

12.

Our products are

oven-cured

a second time

13.

Hand sanded

again to provide a smooth surface for

topcoat

14.

Some finishes receive a

shading

technique

15.

The surface is again

hand sanded

16.

Hand wiped

with tack cloth in preparation for final topcoat

17.

Inspected

for consistency of shading or glazing

18.

A

third coat

of sealer is applied

19.

The surfaces are

hand sanded

again

20.

Resin blend

melamine enriched

topcoat is applied

21.

Conversion varnish topcoat is oven cured, creating a tough,

baked-on finish

22.

Personally

quality inspected

using a sheen meter

23.

UV drying station

completes the curing process

24.

Finished wood components are stored in

individual staging racks

to prevent scratches

Wellborn takes great pride and care with the finishing of our kitchen furniture. Years of research partnered with development through

Valspar have resulted in The WellGuard Finishing System— a 24-step superb finishing process. Shown below are some of the key quality

aspects of our finishing process which all of our stained finishes receive.

To build a base for

the topcoat, surfaces

are hand sanded after

each coat of sealer

guaranteeing a smooth

even finish.

Doors, drawer fronts and

face frames are individually

inspected for a smooth

flawless surface that is

properly prepared for The

WellGuard Finishing System.

The 20 person

manual sanding

line and hand

orbital sanding

processes provide

a consistent finish.

After the color stain is

high pressure sprayed,

the surfaces are hand

rubbed to enhance

the wood grain

characteristics.

Stains are applied

using hand-held spray

equipment.

WellGuard Finish System

The WellGuard Finishing System has been tested against 17 common household chemicals and food

products and passed beautifully. Those agents include:

•

Gasoline

•

Water

•

Coffee

•

Olive Oil

•

Ammonia

•

Fly Spray

•

Detergent

•

Soaps

•

Alcohol

•

Mustard

•

Crayons

•

Shoe Polish

•

Tea

•

Vinegar

•

Dye

•

Citric Acid

•

Beet Juice